ABSTRACT

This paper presents a power factor corrected (PFC) bridgeless

(BL) buck–boost converter-fed brushless direct current (BLDC) motor drive as a

cost-effective solution for low-power applications. An approach of speed

control of the BLDC motor by controlling the dc link voltage of the voltage

source inverter (VSI) is used with a single voltage sensor. This facilitates

the operation of VSI at fundamental frequency switching by using the electronic

commutation of the BLDC motor which offers reduced switching losses. A BL

configuration of the buck–boost converter is proposed which offers the

elimination of the diode bridge rectifier, thus reducing the conduction losses

associated with it. A PFC BL buck–boost converter is designed to operate in

discontinuous inductor current mode (DICM) to provide an inherent PFC at ac

mains. The performance of the proposed drive is evaluated over a wide range of

speed control and varying supply voltages (universal ac mains at 90–265 V) with

improved power quality at ac mains. The obtained power quality indices are

within the acceptable limits of international power quality standards such as

the IEC 61000-3-2. The performance of the proposed drive is simulated in

MATLAB/Simulink environment, and the obtained results are validated

experimentally on a developed prototype of the drive.

KEYWORDS:

1.

Bridgeless

(BL) buck–boost converter

2.

Brushless

direct current (BLDC) motor

3.

Discontinuous

inductor current mode (DICM)

4.

Power factor

corrected (PFC)

5.

Power quality.

SOFTWARE: MATLAB/SIMULINK

CIRCUIT

DIAGRAM:

Fig. 1. Proposed BLDC motor drive

with front-end BL buck–boost converter.

EXPECTED SIMULATION RESULTS:

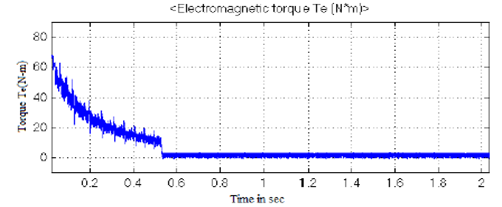

Fig.

2. Steady-state performance of the proposed BLDC motor drive at rated conditions.

Fig.

3. Harmonic spectra of supply current at rated supply voltage and rated loading

on BLDC motor for a dc link voltage of (a) 200 V and (b) 50V.

Fig.

4. Dynamic performance of proposed BLDC motor drive during (a) starting, (b)

speed control, and (c) supply voltage variation at rated conditions.

Fig.

5. Harmonic spectra of supply current at rated loading on BLDC motor with dc

link voltage as 200 V and supply voltage as (a) 90 V and (b) 270 V.

Fig.

6. Steady-state performance of the proposed BLDC motor drive at rated

conditions with dc link voltage as (a) 200 V and (b) 50 V.

CONCLUSION

A

PFC BL buck–boost converter-based VSI-fed BLDC motor drive has been proposed

targeting low-power applications. A new method of speed control has been

utilized by controlling the voltage at dc bus and operating the VSI at

fundamental frequency for the electronic commutation of the BLDC motor for

reducing the switching losses in VSI. The front-end BL buck–boost converter has

been operated in DICM for achieving an inherent power factor correction at ac

mains. A satisfactory performance has been achieved for speed control and

supply voltage variation with power quality indices within the acceptable limits

of IEC 61000-3-2. Moreover, voltage and current stresses on the PFC switch have

been evaluated for determining the practical application of the proposed

scheme. Finally, an experimental prototype of the proposed drive has been

developed to validate the performance of the proposed BLDC motor drive

under

speed control with improved power quality at ac mains. The proposed scheme has

shown satisfactory performance, and it is a recommended solution applicable to

low-power BLDC motor drives.

REFERENCES

[1] C.

L. Xia, Permanent Magnet Brushless DC Motor Drives and Controls. Hoboken,

NJ, USA: Wiley, 2012.

[2] J. Moreno, M. E. Ortuzar, and J. W. Dixon,

“Energy-management system for a hybrid electric vehicle, using ultracapacitors

and neural networks,” IEEE Trans. Ind. Electron., vol. 53, no. 2, pp.

614–623, Apr. 2006.

[3] Y.

Chen, C. Chiu, Y. Jhang, Z. Tang, and R. Liang, “A driver for the singlephase brushless

dc fan motor with hybrid winding structure,” IEEE Trans. Ind.

Electron., vol. 60, no. 10, pp. 4369–4375, Oct. 2013.

[4] X. Huang, A. Goodman, C. Gerada, Y. Fang, and

Q. Lu, “A single sided matrix converter drive for a brushless dc motor in

aerospace applications,” IEEE Trans. Ind. Electron., vol. 59, no. 9, pp.

3542–3552, Sep. 2012.

[5] H.

A. Toliyat and S. Campbell, DSP-Based Electromechanical Motion Control.

Boca Raton, FL, USA: CRC Press, 2004..